The breath and width of the knowledge Tom Wishon possesses in the golf equipment category has no peer.

Finding truth can be a hard task in today’s constant bombardment of claims stating results that simply do not add up.

Tom Wishon follows a simple reality – let the science and numbers do the talking.

Those seeking to purchase equipment should follow his sage advice before spending unnecessarily and thereby adding even more to one’s frustration level because the desired results are not happening.

Background

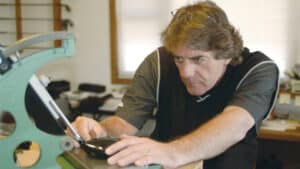

While now semi-retired, Tom Wishon began working with golf clubs in 1972 and became a clubhead designer in 1986. During his career, he has designed over 400 different clubhead models which include over 50 different design firsts, including the first high coefficient of restitution (COR) irons, hybrids, fairway woods in the early 2000s and the first adjustable hosel sleeve for changing woodhead specs in 1995.

Wishon has written 11 books and over 200 articles on the technical performance of golf clubs and club fitting technology for most of the trade and consumer golf publications in the US and internationally.

Two of his books won Golf Book of the Year awards and a number of Wishon’s books are still used as part of the required curriculum for membership in the PGAs of Great Britain, Germany, Sweden and the Netherlands.

The Wishon Story

Several people played major roles in Tom’s career and personal development.

Dick Billehus was the head pro at Greeley CC (located halfway between Denver and Fort Collins, CO) in the city where he grew up and learned to play golf. Billehus was the first to introduce him to working on golf clubs in high school which began his interest.

Chinneng Lin, owner and founder of Dynamic Precision Casting Corporation, today the third largest manufacturer of clubheads in the golf industry.

Chinn owned half of Dynacraft Golf Company when Tom was the company president from 1986 to 1993. Over the course of those years Chinn allowed Wishon to spend a total of nearly 7 months in his factory learning every single aspect of clubhead engineering and production technology.

Art Mittendorf, a former Air Force Top Gun instructor with two engineering degrees, Art was Tom’s engineering mentor from 1993 to 2006.

During that time Mittendorf helped teach him the applicable science and engineering facts and principles he used to guide his clubhead design work and research into the performance of golf clubs as well as into club fitting technology.

***

You’ve been in the golf industry for quite some time. How are things different now than when you first started?

You’re talking to a living dinosaur when it comes to the state of golf club design when I started! Meaning I lived through, and am very proud of my contributions to the evolution of drivers and woods being made from trees to real science being the key part of all clubhead design today!

But it has been a blast to be part of it and I am proud of how scientifically sound clubhead design is today. Problem is, when that excellence is used to only make clubs to be sold in standard form off the rack, it falls well short of helping golfers as much as it could.

The holiday season is now upon us. What advice would you give to someone not familiar with golf equipment who is looking to purchase something for an avid player?

Do the research to find an independent custom clubmaker / club fitter as close to the holiday gift recipient as possible and buy them a gift certificate for a professional club fitting analysis.

And I mean independent custom clubmaker. Not a big box golf retail store.

You’ve been a long-time advocate of meaningful golf club configuration in terms of the clubs used by a player. What’s the percentage of players that can carry a 5-iron and lower in their bag?

What is the percentage of golfers who cannot swing a 5-iron over 70-75mph? That’s your answer.

It takes that much clubhead speed to generate the required ball speed to get an iron of today’s average 5-iron loft — 22 to 25 degrees — to fly well up in the air to maximize carry distance to make having the 5-iron worthwhile in your bag.

That’s pure physics and has nothing to do with the design of the 5-iron head.

How often should players be fitted for clubs?

Once you get fitted by a knowledgeable and experienced custom clubmaker, your custom fit clubs will fit you until one or both of the following happens in your game:

1) Increase or decrease in clubhead speed of 10mph or more.

2) Major swing change in swing path, point of release in the downswing, or angle of attack into the ball.

For as long as your speed and key swing elements do not change much, your properly fit clubs will perform as well as possible for you.

Club fitting is a central emphasis point you’ve long championed. What’s the percentage of competent people who do such fittings consistently well?

Very small and getting smaller every year. And I assure you the best clubmakers do not work in big box retail golf stores.

Because it takes a long time for a golfer passionate about fitting and equipment to learn the depth of skills and knowledge required to be a competent club fitter.

If you’re interested in club fitting, whether to be one or to find one, contact the Association of Golf Club Fitting Professionals and ask for help.

The USGA / R&A announced a short time ago that starting in 2028 for elite players and in 2030 for all others the golf ball will be rolled back. Do you agree an action was needed and with that happening in the manner planned?

No, I was adamantly against the roll back of the ball.

Compelling competition in golf is not about how far anyone hits the driver or what club they hit into the green. It’s about how many players are within 1-2 shots of the lead going into the back nine of any tournament.

I think it will take a lot away from the game to have to accept that we mortals will be playing with a different ball than the best players in the world.

There’s been speculation once the rollback of the golf ball takes place – there will be movement to minimize distance gains made by driver clubs. How do you view such action if that should happen?

The USGA/R&A already have adequate rules in place to prevent driver distance from increasing any more than where it is at present.

The only thing that will bring about more distance is player training and conditioning. Which is something I do hope the USGA/R&A keep their noses out of. Because if athletic individuals continue to diligently pursue training for increasing clubhead speed, the only way the ruling bodies can prevent more distance is to put a limit on clubhead speed.

Now can you imagine that?

Related: Brian Costello interview

Are there other actions that could be taken – such as lowering the max number of clubs to say ten? Or in prohibiting any iron to be greater than 56 degrees of loft? Thoughts?

I’m very much against the constant lowering of iron lofts by companies greedy for your purchases.

Despite what they feed you, the only reason 5 irons today are 22-25 degrees in loft vs the 32 degrees they were when I began my career is to fool golfers into thinking the new iron technology is the reason you hit a modern iron set longer per club than what you used ten+ years ago, to lead to you forking over your plastic to buy that new set.

So yeah, I’d like to see a limit on what the loft of each iron should be. Then you’d see when real iron design technology matters.

Has pure shotmaking been lessened given the nature of how equipment is manufactured today?

I don’t think so. Players like Tiger in 2000 or Scottie in 2024 come about simply because they became markedly more consistent and repetitive in their swings and strokes than the other players.

OK, I can say that proper fitting helps that a little, but seriously, the level of consistency shown by those guys in their top years has nothing to do with club design.

To me the purest form of shotmaking is how often can you repeat that swing that puts the ball where you want it to go.

And that is the archer, not the arrow.

You’ve prided yourself in being candid on all aspects relating to golf equipment. Do you see such candor as being more valued today than when you first came onto the scene?

Valued? Hardly.

For my candor about how proper fitting and truthful information about golf clubs to make a real difference for regular golfers would require me to win the lottery so I could spend $100 million to push that message to the point of it actually being heard.

My knowledge is like a fart in the windstorm of marketing of the big golf companies. How’s that for the candid truth?

***

For more info go to:

Wishon Golf – www.wishongolf.com – www.agcpgolf.com